Marion Process Solutions

Cannabis & Hemp Processing Equipment

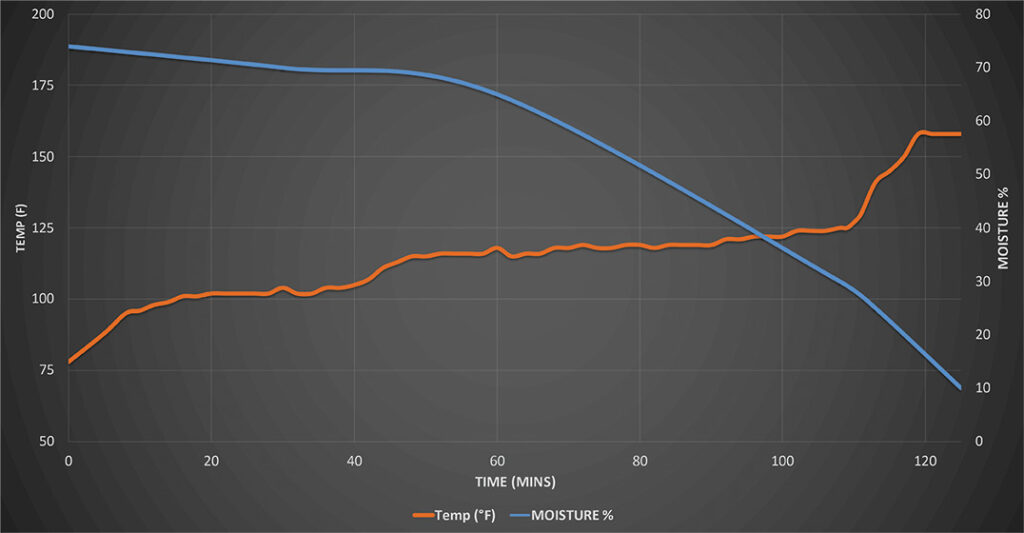

Real Results: From 77% to 9% in 45 Minutes

After some research on drying technology, you may be wondering about the real results you can get when moving to industrial thermal processing of cannabis flowers and hemp. Here’s the reality. Marion’s WaveMix™ Thermal Processor has been tested and validated by third parties:

- In just 45 minutes, moisture in hemp flowers was reduced from 77% to 9%

- THC content went from 0.33% to 0.23%

- CBD content went from 11.46% to 11%

- Total Terpene content went to 2.58% to 1.06%

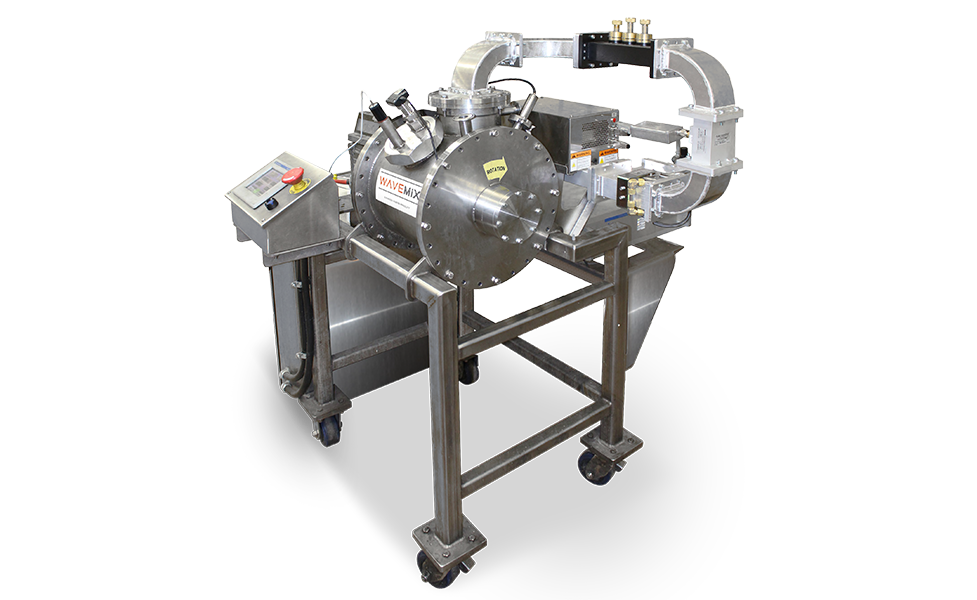

WaveMix Cannabis accomplishes these results using direct heating, that is, microwave technology, along with vacuum for protecting the quality of the product. Learn more about the results your peers are getting and how you too can benefit from Marion’s thermal processing solutions.

For more information about thermal processing and cannabis product processing, please check out these resources:

- Thermal Processing Handbook: A great overview of industrial thermal processing, the many types of equipment and the pros and cons of each.

- Blogs on cannabis processing: Cannabis Processing: The Importance of Thermal Processing Equipment and 5 Things to Look for in Your Hemp Drying Equipment

- Our product catalog of WaveMix solutions for drying cannabis and hemp, along with their features, functions and benefits.

- Interested in learning more about our WaveMix Cannabis product? Download this product sheet or reach out to us directly about WaveMix Cannabis here.

Drying results for industrial thermal processing of cannabis flowers and hemp

Drying results for industrial thermal processing of cannabis flowers and hemp

Explore Typical Cannabis/Hemp Industry Configurations

WaveMix™ Lab Unit | Custom Options Industries: Food & Beverage, Plastics, Minerals, Chemicals, Biomass, Cannabis/Hemp, Pharmaceutical / Nutraceutical, Coffee

View Configuration Details