Marion Process Solutions

Core Series

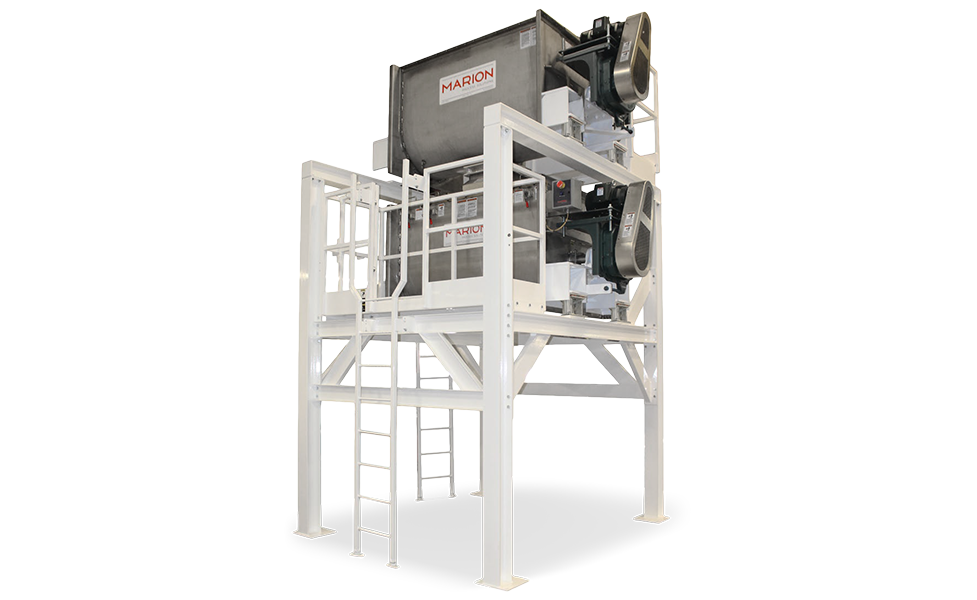

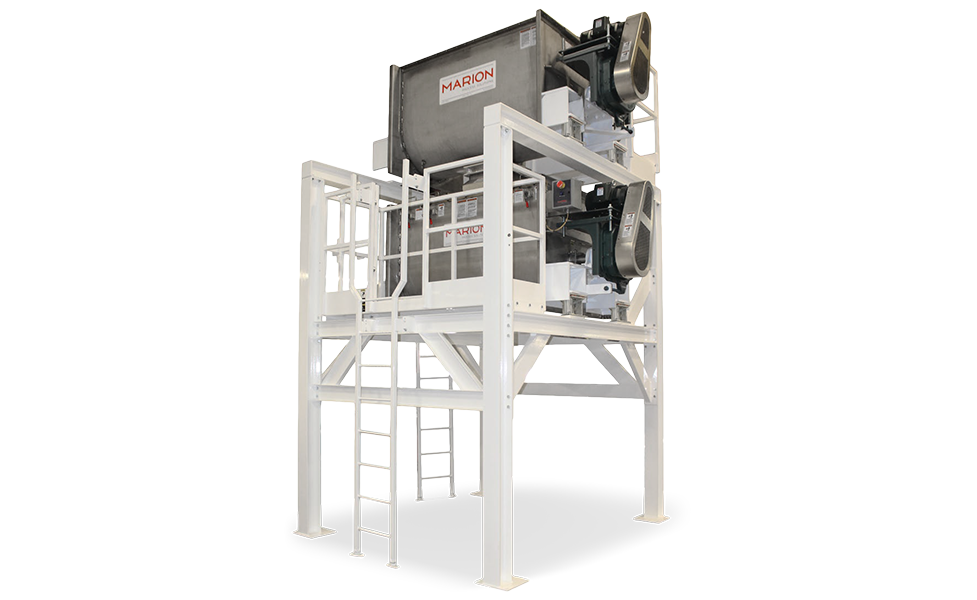

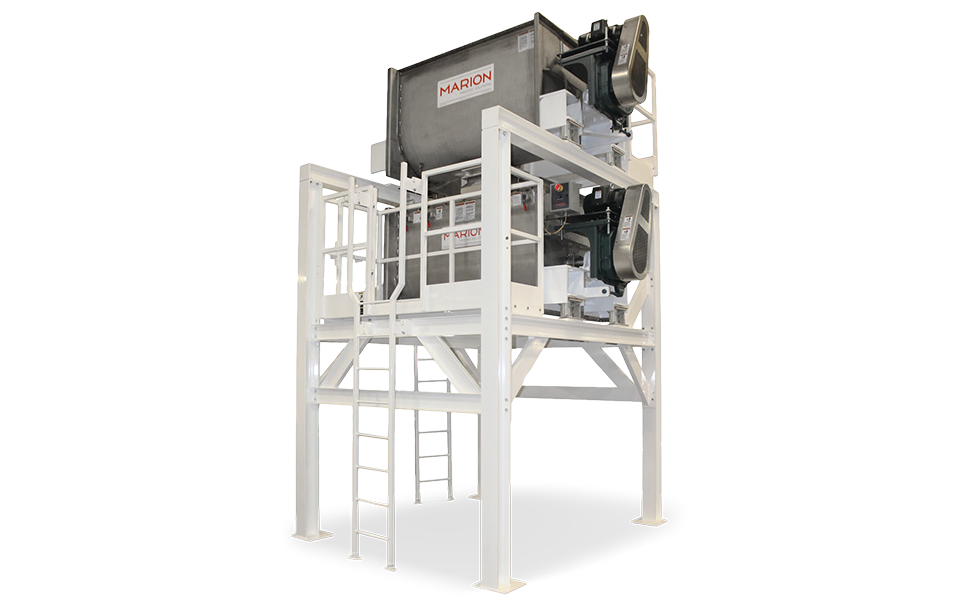

Mineral, Pharmaceutical & Nutraceutical Mixing Configurations

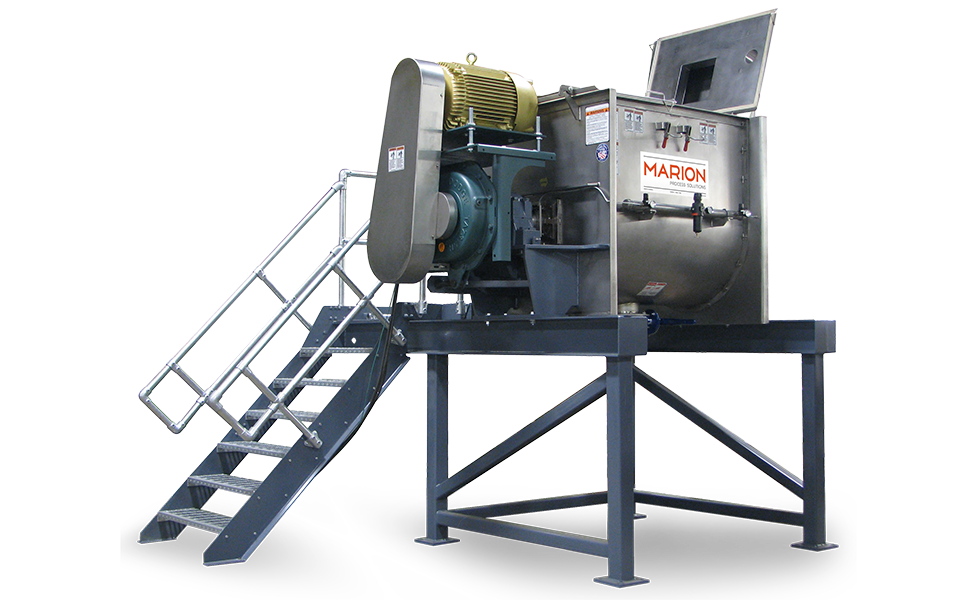

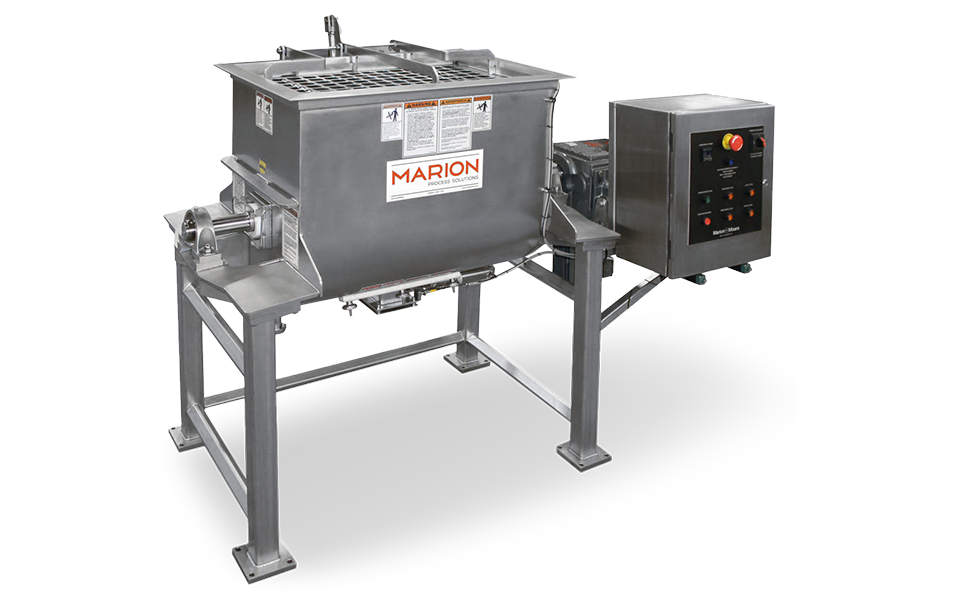

The convenience of a batch processing system integrated into a mezzanine support structure creates a competitive advantage in this powder application. The flexibility to produce premixes or surge batches provides the perfect amount of versatility.

For more information on Marion mixers, visit our visit our Horizontal Batch Mixer Product Page.

Similar Solutions

Here are a few examples of other related configurations.

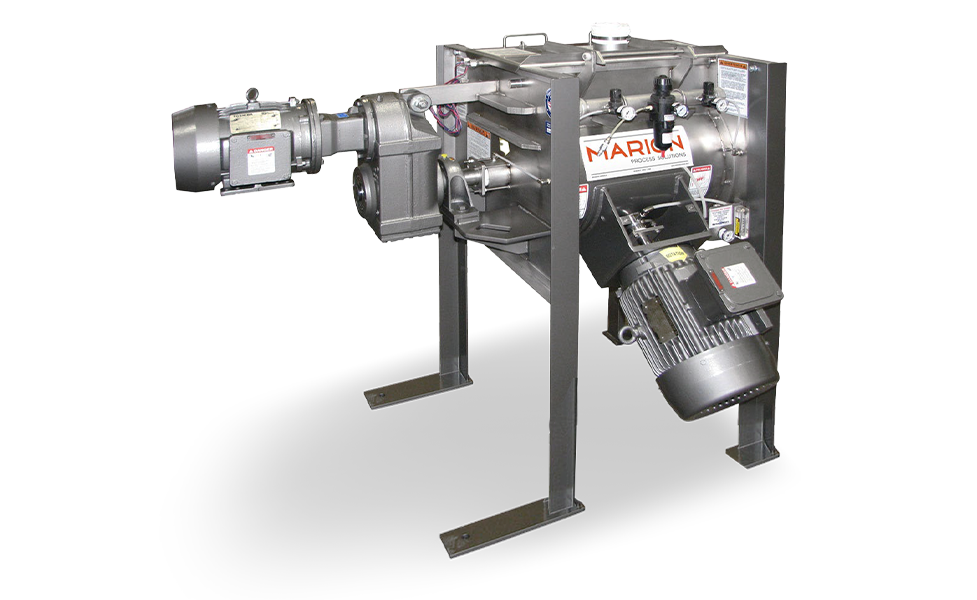

Small-to-Medium Horizontal Batch Mixer Configuration Industries: Plastics, Minerals, Chemicals

View Configuration Details

Mineral, Pharmaceutical & Nutraceutical Mixing Configurations Industries: Minerals, Pharmaceutical / Nutraceutical

View Configuration Details

Animal Nutrient & Feed Processing Equipment Configuration Industry: Minerals

View Configuration Details

Bakery Ingredient Mixer Configuration Industry: Food & Beverage

View Configuration Details

Flavor Dosing System Configurations Industries: Food & Beverage, Coffee

View Configuration Details

Flour Blending Equipment Configuration Industry: Food & Beverage

View Configuration Details

Grout Powder Processing Equipment Configuration Industry: Minerals

View Configuration Details

Nutraceutical Powder Blending Equipment Configuration Industry: Pharmaceutical / Nutraceutical

View Configuration Details

Food Crumbling Mixer Configuration and Custom Options Industry: Food & Beverage

View Configuration Details

Animal Nutrient Ingredient Equipment Configuration Industry: Minerals

View Configuration Details

Sulphate Slurry/Polyol Liquid Equipment Configuration Industry: Chemicals

View Configuration Details

Powder, Seasoning & Dehydrated Vegetable Equipment Configuration Industry: Food & Beverage

Marion's decades of expertise in mixing and food processing combined with the following custom options made this batch mixer configuration for food and soup processing possible.

View Configuration Details

Iron Powders & Resin Processing Configuration Industries: Plastics, Chemicals

View Configuration Details

Plastic Pellet Processing Equipment Configuration Industries: Plastics, Chemicals

View Configuration Details

Plastic Powder & Pellet Mixer | Configuration Industries: Plastics, Chemicals

View Configuration Details

Food Grade Resin PVC Processing Configuration Industries: Plastics, Chemicals

View Configuration Details

Nutraceutical Powder Mixing Equipment Configurations Industry: Pharmaceutical / Nutraceutical

View Configuration Details

Pharmaceutical Powder Mixing Equipment Configuration Industry: Pharmaceutical / Nutraceutical

View Configuration Details

Bentonite, Minors & Water Processing Configuration Industries: Minerals, Chemicals

View Configuration Details

Aluminum Powder & Boron Processing Equipment | Configuration Industries: Minerals, Chemicals

View Configuration Details

Borax & Oxide Powder Mixing Equipment Configuration Industries: Minerals, Chemicals

View Configuration Details

Bakery Premix Manufacturing Equipment Configuration Industry: Food & Beverage

View Configuration Details

Chili Powder Processing Mixer Configuration Industry: Food & Beverage

View Configuration Details

Ricotta Cheese Batch Mixer Configuration Industry: Food & Beverage

View Configuration Details

Gelatin Powder Processing Equipment Configuration Industry: Food & Beverage

View Configuration Details

Deli Salad Mixers | Custom Options Industry: Food & Beverage

View Configuration Details