Marion Process Solutions

Explore Our Material Processing Resource Library

There is a lot of information out there, so we appreciate you coming to us. We’ve prepared educational e-books and webinars with experts to help you make informed decisions. Want to learn everything about thermal processing? We have that handbook—with all the different types, pros and cons of each! Mixers got you all mixed up about what to pick? We have a full breakdown of agitators and more to help you better make the right choice for your application. See below, and if none of these (or our blogs!) answer your questions, reach out directly—we can’t wait to Connect!

Almac Pharma Services Case Study

Almac Pharma Services has installed Marion Process Solutions blending equipment at their production facility in Ireland. This video provides an overview of the equipment supplied by Marion and includes feedback from Almac's team on their experience working with both Marion and Kason. Our team supplied Almac with two Marion 400L (14 ft³) V-Cone Blenders, two Marion 4200L (148 ft³) Double-Cone Blenders, and Kason Centrifugal Sifters.

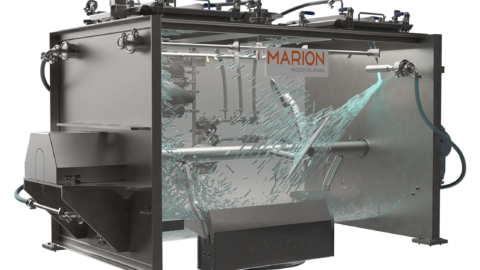

Clean-in-Place (CIP) for Industrial Processing: Benefits & How It Works

Get more consistent results in a fraction of the time of manual cleaning with Marion’s TotalClean CIP System. Automated technology and high-pressure nozzles deliver the power to clean hard-to-reach spots helping you speed up batch changes and increase product throughput.

CIP Brochure

Get more details on our fixed and mobile CIP systems including the features you can add to customize your system.

AMP 2023 Product Catalog

Advanced Material Processing brings together manufacturers of industry-leading material processing equipment to help customers improve production and widen profit margins.

Marion 2023 Product Catalog

There are many factors that go into selecting the right machine for your application – everything from what material you’re processing to whether you need it to be pharmaceutical-grade. But Marion’s expert application engineers work with you every step of the way, making sure you get a machine that’s a perfect fit for your specifications and production needs.

Thermal Processing Handbook

Thermal processing equipment is vital technology in the manufacturing process of food, pharmaceutical, chemicals and numerous other types of applications. Thermal processing refers to changing the temperature of a material with the intention of changing its state in some way.

AMP Full Product Catalog - German

Advanced Material Processing brings together manufacturers of industry-leading material processing equipment to help customers improve production and widen profit margins. Download this catalog for full complement of Kason and Marion Product offering

Are You Getting the Most Out of Your Process?

There’s a reason why so many companies put their trust in our brands. Our expert application engineers and lab technicians have helped improve processing for all types of industries – everything from increasing throughput to minimizing mixing time. Learn about the steps we take to ensure optimized and effective testing with YOUR materials on Kason and Marion equipment.

Driving Performance in Chemical Mixing

Every chemical manufacturer, chemical plant engineer and quality manager recognizes the need to optimize four core considerations with the right equipment. Read how to achieve your chemical mixing goals and what new tools are available to get you there.

Horizontal Continuous Mixer Specifications

A reference chart for capacity and dimensional specifications for Marion Horizontal Continuous Mixers.

Horizontal Batch Mixer Specifications

A reference chart for capacity and dimensional specifications for Marion Horizontal Batch Mixers.

Say No to the 5-Second Rule

When it comes to safety and compliance, the 5-second rule just doesn’t cut it. Listen in on this webinar to learn about food safety, compliance and design consideration, hosted by the experts in food screening, sifting, mixing and blending.

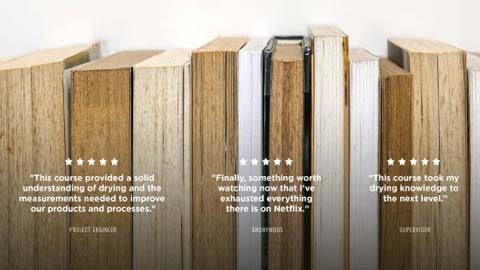

Pursuit of Dryness

Get exclusive thermal processing information from our Thermal Drying Industry Expert, James Schak. Learn about the different forms of drying and what may be best for your application in this highly attended webinar co-hosted with our sister company, Kason Corporation.

O-Ring vs. Tape Gaskets

Marion Process Solutions shares the benefits of using an o-ring gasket vs. the old tape gasket. Tired of the same old issues with tape gasketing?—like dusting, not staying put, inability to clean or even remove after extended use? Marion created an o-ring gasket that stays put, gives an air-tight seal, keeps any dusting at bay and is cleanable (in a matter of seconds!) and replaceable.

WaveMix by Marion Process Solutions

The new wave in industrial mixing, heating and drying -- Wavemix unlocks your potential by using microwaves to generate returns in your application. Microwaving a fluid bed of product creates the advantage of shorter processing time, uniform material temperature and the flexibility to operate under pressure, vacuum, and/or nitrogen blanket. With WaveMix, your return on investment is easily calculated as test results translate directly into production equipment.

Paddle Mixers

Choosing 3-A authorized equipment is the right way to go. If it says "compliant” or “certified” you can be pretty sure it’s not authorized. Marion has the only 3-A authorized horizontal mixer on the market today. Learn more about Marion Process Solutions' Paddle Mixer with 3-A Authorization.

Cannabis Processing Brochure

Cannabis processing is a high-precision proposition. Better care and handling of material leads to higher yields and lower risks to growers and processors. Learn more about your options in our brochure.

WaveMix™ Cannabis Product Brochure

Learn more about our newest product that uses direct heating for cannabis. Compared to air drying, with microwave processing from Marion, there are a lot of benefits.

Industrial Food Mixing Guide

Learn how to choose the right mixer for the bakery, coffee, nutraceutical and ready-to-eat verticals plus ways to improve sanitary conditions with the right seals, gaskets and replaceable parts in our Industrial Food Mixing Guide.

Choosing the Right Industrial Mixer Handbook

If you’re in the market for mixing equipment, it’s important to ask the right questions and understand the fundamentals of mixer design. With this insight, you can ensure your mixer will be designed to suit your processing needs. Marion’s Mixing Handbook is the place to start when selecting an industrial mixer for food, pharmaceutical, chemical, biomass, and mineral applications.

Marion Momentum Series

Moving forward with you. Industrial mixing never stands still, and Marion Process Solution has remained a leader for more than 80 years by growing and developing with its customers. The latest product line from Marion, the Momentum Series, provides an even wider range of products than ever before, all made in the USA with our expert craftsmanship. Introducing the Fluidizing Paddle Mixer, the V Cone Blender, the Double-Cone Blender and the NEW Lump Breaker. Share the Momentum.

Momentum Series Product Launch

Launched in later 2020, check out our quick half hour overview of the three new Marion Momentum Series mixer and blenders, featuring a panel of our experts.