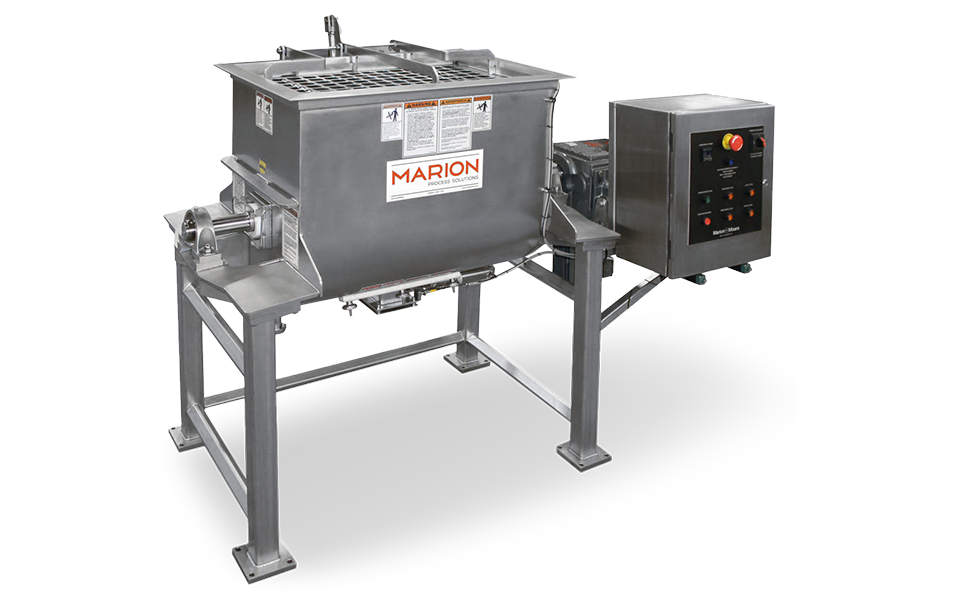

Marion Process Solutions

Core Series

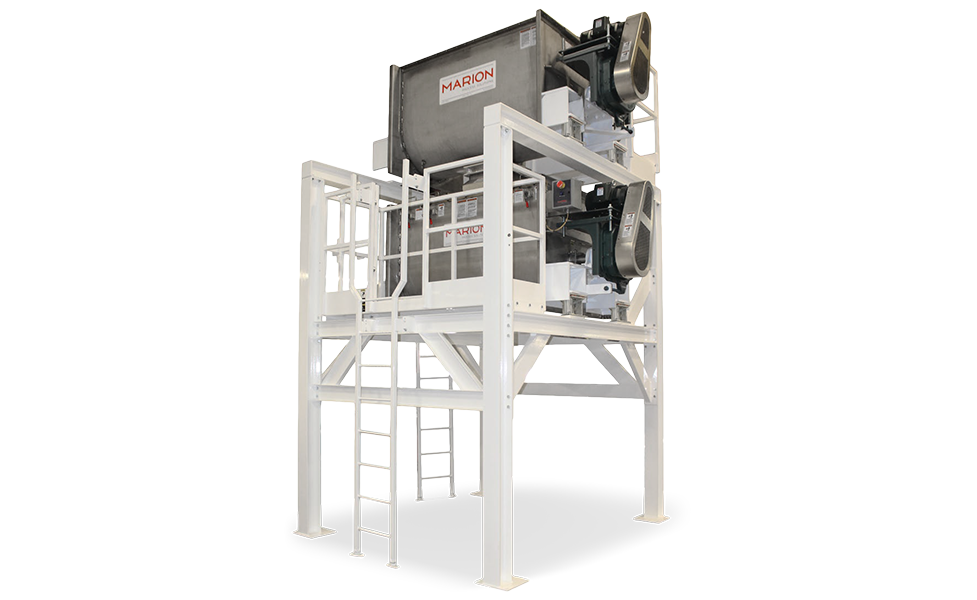

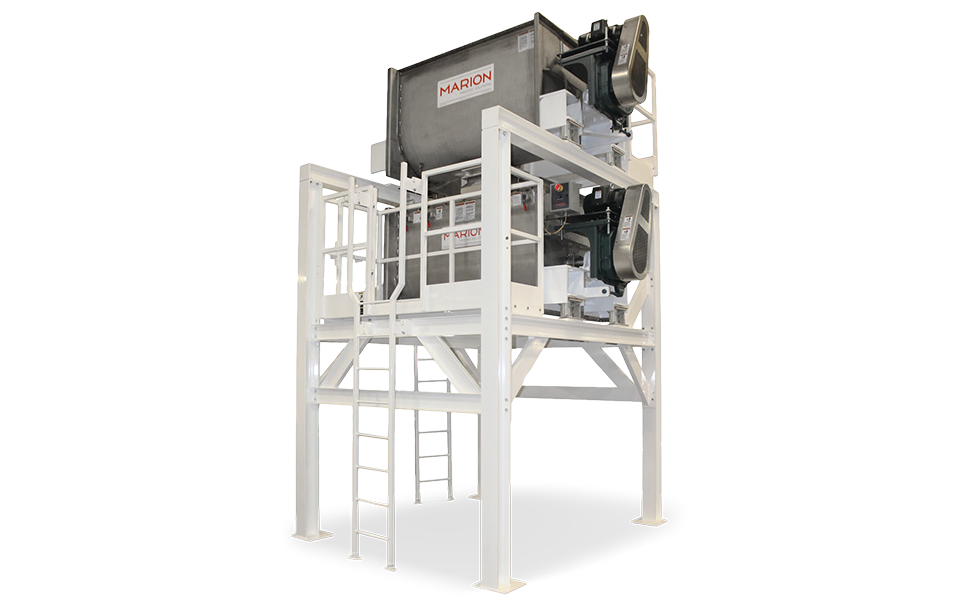

Flavor Dosing Systems | Custom Options

We measure success in percentages; fluid dosing to within 1% of target weight, less than .05% loss of product, 85% decrease in processing time and 400% increase in throughput. Percentages we're ready to delight you with on your project. Add to that the capability of fully automated rinse-in-pace and dry and an HVH Cablevey Conveyor ... and you've got yourself a Marion solution.

Industrial Food Mixing Application Guide

How to choose the right mixer for the bakery, coffee, nutraceutical and ready-to-eat verticals plus ways to improve sanitary conditions with the right seals, gaskets and replaceable parts

DOWNLOAD NOWSimilar Solutions

Here are a few examples of other related configurations.

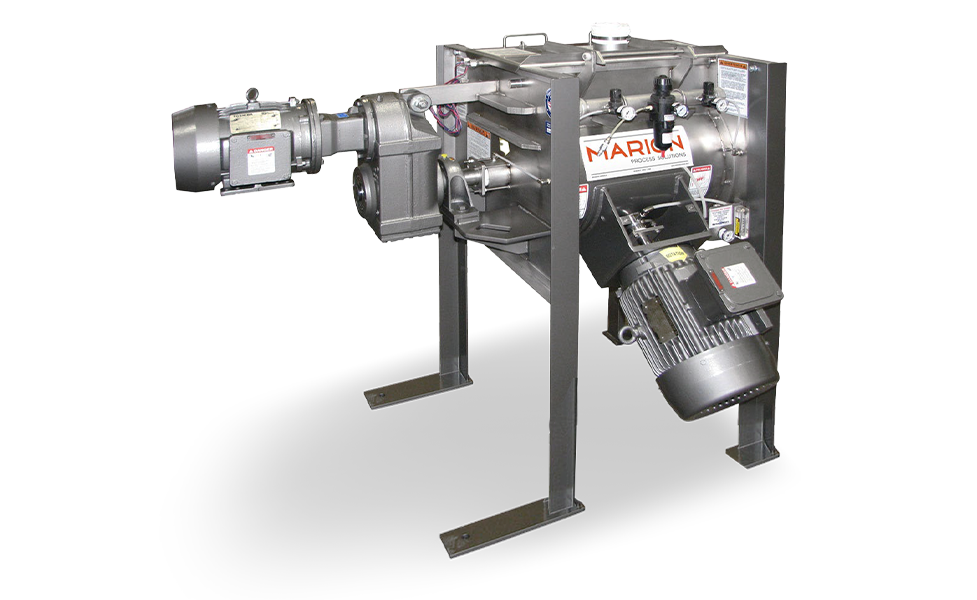

Reliable and Hardworking Ox Mixers | Custom Options Industries: Plastics, Minerals, Chemicals

View Configuration Details

Mineral, Pharmaceutical & Nutraceutical Mixing | Custom Options Industries: Minerals, Pharmaceutical / Nutraceutical

View Configuration Details

Animal Nutrient & Feed Processing Equipment | Custom Options Industry: Minerals

View Configuration Details

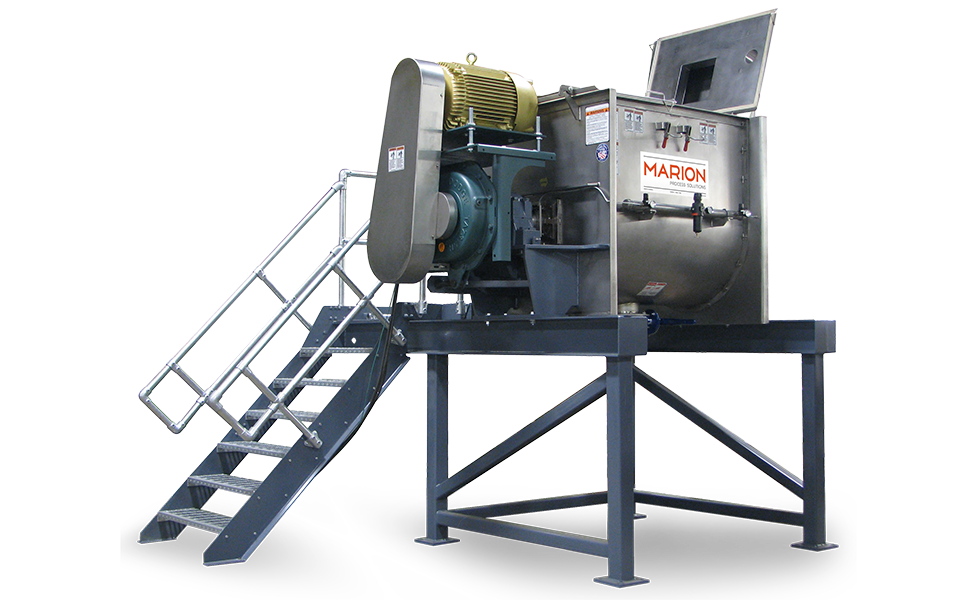

Bakery Ingredient Mixer | Custom Options Industry: Food & Beverage

View Configuration Details

Flavor Dosing Systems | Custom Options Industries: Food & Beverage, Coffee

View Configuration Details

Flour Blending Equipment | Custom Options Industry: Food & Beverage

View Configuration Details

Grout Powder Processing Equipment | Custom Options Industry: Minerals

View Configuration Details

Nutraceutical Powder Blending Equipment | Custom Options Industry: Pharmaceutical / Nutraceutical

View Configuration Details

Food Crumbling Mixer | Custom Options Industry: Food & Beverage

View Configuration Details

Animal Nutrient Ingredient Equipment | Custom Options Industry: Minerals

View Configuration Details

Sulphate Slurry/Polyol Liquid Equipment | Custom Options Industry: Chemicals

View Configuration Details

Powder Seasoning & Dehydrated Vegetable Equipment | Custom Options Industry: Food & Beverage

View Configuration Details

Iron Powders & Resin Processing | Custom Options Industries: Plastics, Chemicals

View Configuration Details

Plastics: Coloring Plastic Pellets Industries: Plastics, Chemicals

View Configuration Details

Plastic Powder & Pellet Mixers | Custom Options Industries: Plastics, Chemicals

View Configuration Details

Food Grade Resin PVC Processing | Custom Options Industries: Plastics, Chemicals

View Configuration Details

Nutraceutical Powder Mixing Equipment | Custom Options Industry: Pharmaceutical / Nutraceutical

View Configuration Details

Pharmaceutical Powder Mixing Equipment | Custom Options Industry: Pharmaceutical / Nutraceutical

View Configuration Details

Bentonite, Minors & Water Processing | Custom Options Industries: Minerals, Chemicals

View Configuration Details

Aluminum Powder & Boron Processing Equipment | Custom Options Industries: Minerals, Chemicals

View Configuration Details

Borax & Oxide Powder Mixing Equipment | Custom Options Industries: Minerals, Chemicals

View Configuration Details

Bakery Premix Manufacturing Equipment | Custom Options Industry: Food & Beverage

View Configuration Details

Chili Powder Processing Mixer | Custom Options Industry: Food & Beverage

View Configuration Details

Ricotta Cheese Batch Mixer | Custom Options Industry: Food & Beverage

View Configuration Details

Gelatin Powder Processing Equipment | Custom Options Industry: Food & Beverage

View Configuration Details

Deli Salad Mixers | Custom Options Industry: Food & Beverage

View Configuration Details